Without the model from JARC, work would have been delayed as we waited for the EOR to develop a solution. The model allowed us to take a proactive approach and provide a coordinated solution that worked for both us and our subsAlex Gipson, Project Manager with McLean Contracting Co.

As-built shots taken along an existing L-shaped sheet pile quay wall indicated a 2’ bi-directional discrepancy from the locations provided on the design plans. McLean Contracting Co. (McLean) and J.A.Roberts Co. (JARC) minimized construction delays by proactively adjusting design geometry to reflect the as-built conditions using a 3D model.

Existing sheeting as-builts uncover layout discrepancy

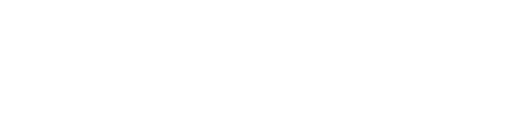

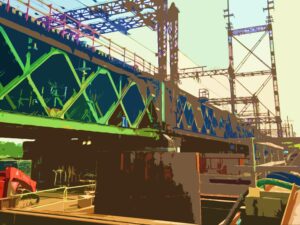

The project involved the construction of a new naval pier and an adjacent quay wall. A ramp connected the main pier to the lower elevation of the quay wall. The new quay wall incorporated existing sheet piles and supported a new elevated utility platform, which featured a stairway providing access to the main pier that ran parallel to the ramp.

During early construction of the quay wall, an as-built survey of the existing sheet pile was performed. The actual location of the existing wall was offset 2’ bi-directionally from the location shown in the design plans. This discrepancy impacted critical work associated with the quay wall and the ramp to the main pier.

At the time when the sheet pile as-built discrepancy was identified, shop drawing submission, shop fabrication, and field work on the main pier had already begun.

Quay wall geometry adjusted in model

Under a prior scope, JARC modeled the entire design to vet design geometry and perform clash detection. Using as-built data provided by McLean field survey teams, JARC utilized the model to compare as-builts to design, identify discrepancies, and quantify their implications.

JARC analyzed each feature affected in the model to determine the minimum necessary adjustments that would cause the least impact to existing operations. The model was reviewed for clashes and updated to reflect as-built data and proposed changes. After the model was updated, it was shared with the Engineer of Record (EOR) who then approved the proposed changes.

The new model was used to provide information to project team including McLean, subcontractors, fabricators, and EOR. Coordination between the various parties was essential to ensure all features were detailed properly to fit-up in the field. JARC provided the following coordination:

- Layout data was extracted from the model and provided to McLean field survey teams for concrete layout.

- Cut-off elevations for the concrete pile at the ramp were determined from the model and provided to the McLean field survey teams.

- Concrete formwork drawings were reviewed and marked-up to provide the formwork subcontractor with feedback to ensure fit-up based on the model geometry.

- Data was extracted from the model and provided to the rebar detailer so adjustments could be made to rebar shop drawings.

- Shop drawings provided by fabricators and subcontractors were reviewed and marked up to communicate the required changes.

- Fabrication shop drawings, previously created by JARC, were adjusted and sent to fabrication.

Work progresses with minimal delay

As a result of the coordinated effort, McLean proceeded working with minimal delay, subcontractor work advanced with clear direction and fabricated elements fit-up during field installation.

Alex Gipson is a Project Manager with McLean Contracting Co. and played a major role in the project coordination involving the model.

“Without the model from JARC,” he says ”work would have been delayed as we waited for the EOR to develop a solution. The model allowed us to take a proactive approach and provide a coordinated solution that worked for both us and our subs.”

With regards to the cost of the model, Alex viewed it as an investment. “The amount spent on the model saved us several times that in construction cost throughout the project. It was absolutely necessary to model this job.”

Learn more about McLean Contracting Co. at their website https://mcleancontracting.com/