Conventional practice suggests that fabricators should provide the shop drawings for temporary works. After all, these drawings are “shop” documents, used to direct cutting, welding, and assembly operations. Fabricators also have the technical expertise and detailing knowledge to produce them efficiently.

But what are the real costs of relying on fabricators for temporary works shop drawings? A deeper look uncovers risks and inefficiencies that point to a better path: contractors taking control of the shop drawing process.

Temporary works vs permanent works

It’s important to first distinguish between temporary works and permanent works.

For permanent works, such as plate girders and columns, relying on fabricators for shop drawings makes sense. Permanent elements are standardized, repetitive, and less sensitive to field conditions.

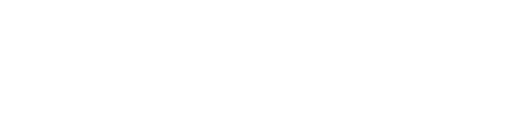

For temporary works, however, the situation is very different. Temporary structures (e.g., falsework bents, shoring, and bracing) are often unique, highly customized, and deeply tied to project-specific means and methods.

This uniqueness introduces variables beyond fabrication and final geometry, variables that contractors understand best. When fabricators lead the drawings, those variables are often overlooked, leading to hidden costs.

Cost #1: Poor integration with the field

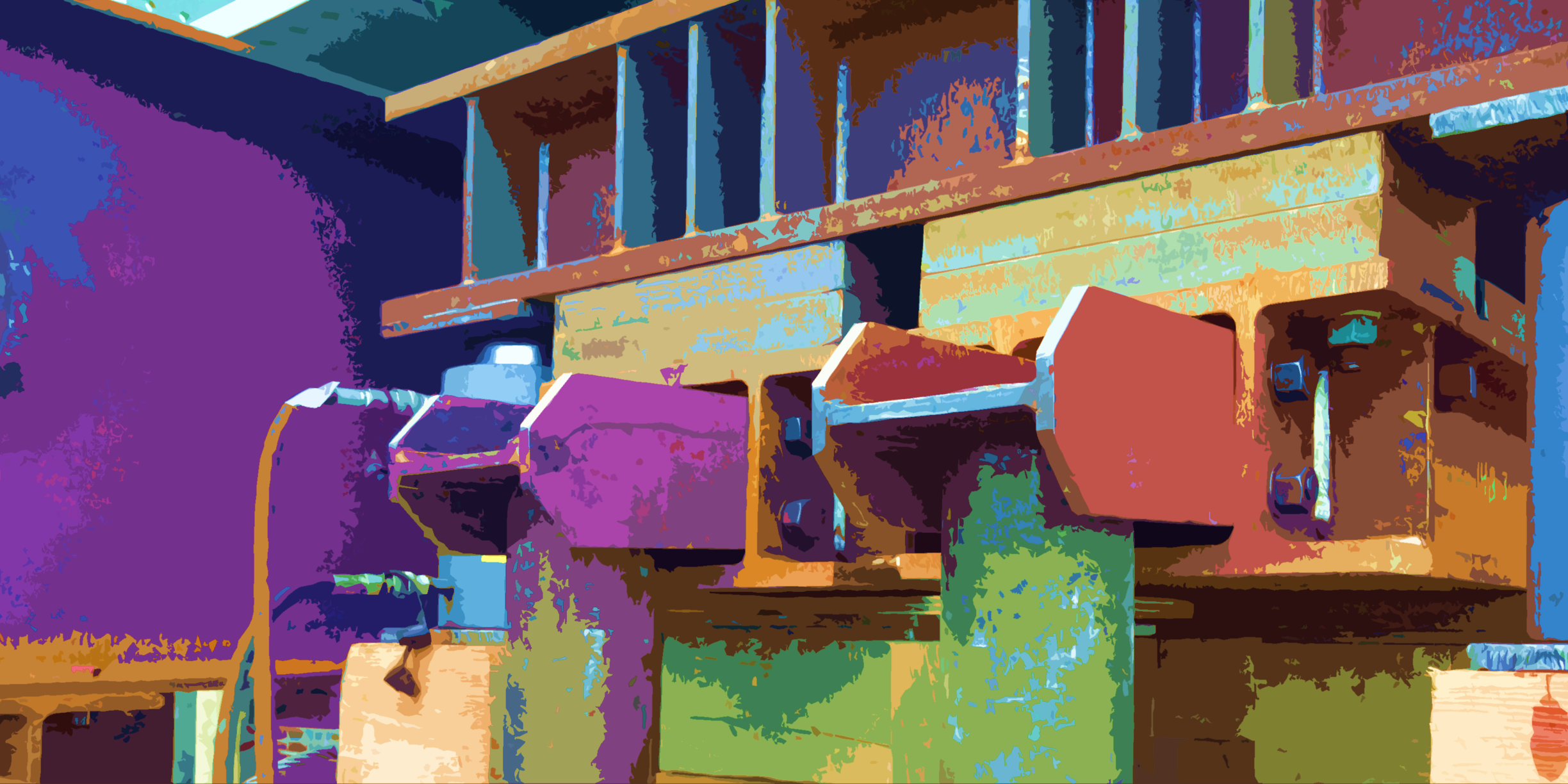

Even though shop drawings are produced for the shop, the pieces are erected in the field. If temporary works shop drawings fail to account for field geometry, tolerances, and construction sequencing, the result is costly field modifications. Torch-cutting and welding onsite are far more expensive, time-consuming, and disruptive than when performed in the shop.

Fabricators are focused (and rightfully so) on keeping production flowing. Usually, they do not have sufficient information to understand the contractor’s means and methods. When contractors own the shop drawings, they can ensure these field conditions are built into the design. Done correctly, this eliminates unnecessary field work and minimizes both the cost and complexity of installation.

Cost #2: Unclear direction

Fabricators need direction on what to build. Without formal shop drawings, direction often comes through sketches, redlines, or even vague emails. For simple fabrication, this may suffice, but as

complexity increases, so do the risks of misinterpretation.

This vagueness can lead to mis-fabrication resulting in costly errors that require rework or replacement. Additionally, when the scope is unclear, fabricators tend to protect themselves by providing conservative pricing.

Shop drawings are a universal language fabricators understand. They provide the clearest way to communicate important fabrication details and provide precise, unambiguous direction. However, the drawings must conform to conventional standards. Specific detailing conventions may seem insignificant to the untrained eye but can drastically affect the finished product.

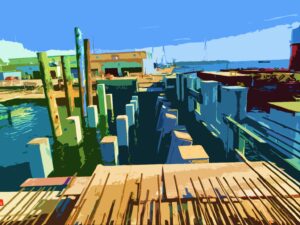

Cost #3: Schedule delays

Unclear direction doesn’t just cost money, it costs time. Discrepancies discovered during fabrication typically trigger lastminute RFIs or changes. These interruptions stall fabrication and push back delivery, which in turn delays construction operations dependent on the temporary works.

By taking responsibility for temporary works shop drawings, contractors perform due diligence earlier in the process. Geometry is vetted against field conditions before fabrication, eliminating last-minute surprises and keeping both shop and field operations on schedule.

Expertise for temporary works shop drawings

Creating temporary works shop drawings requires a special combination of construction, fabrication, and detailing knowledge to:

- Account for all field conditions and variables.

- Provide clear direction using conventional detailing practices.

- Identify discrepancies ahead of time.

A fabricator will naturally bring fabrication and detailing expertise, but they often lack the construction insight and project intimacy required to properly integrate temporary works with the field. Thus, it is crucial that contractors have either in-house engineers with the ability to bridge construction and detailing knowledge, or specialized professionals who can provide this expertise on their behalf. This ensures the drawings are not just technically correct, but fully aligned with field realities and project requirements. By producing and providing these drawings, contractors protect themselves against hidden costs, while enabling fabricators to focus on what they do best: building accurately, efficiently, and on time.