The operation went really well. Field layout and geometry looked just as it was depicted in the drawings from JARCTaylor Moon, Senior Project Engineer at CMJV

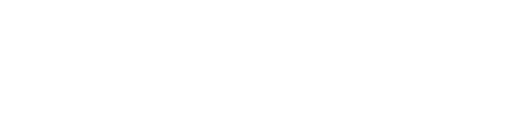

At the WALK Bridge Replacement project in Norwalk, Connecticut, work adjacent to an active railroad and energized overhead utilities required comprehensive construction planning. Together with the Cianbro Middlesex Joint-Venture (CMJV), J.A.Roberts Co. (JARC) utilized 3D scanning (LiDAR) technology to locate existing features and plan operations as part of the preparation to construct foundation components for new vertical lift railroad bridge towers.

Working near railroads presents challenges

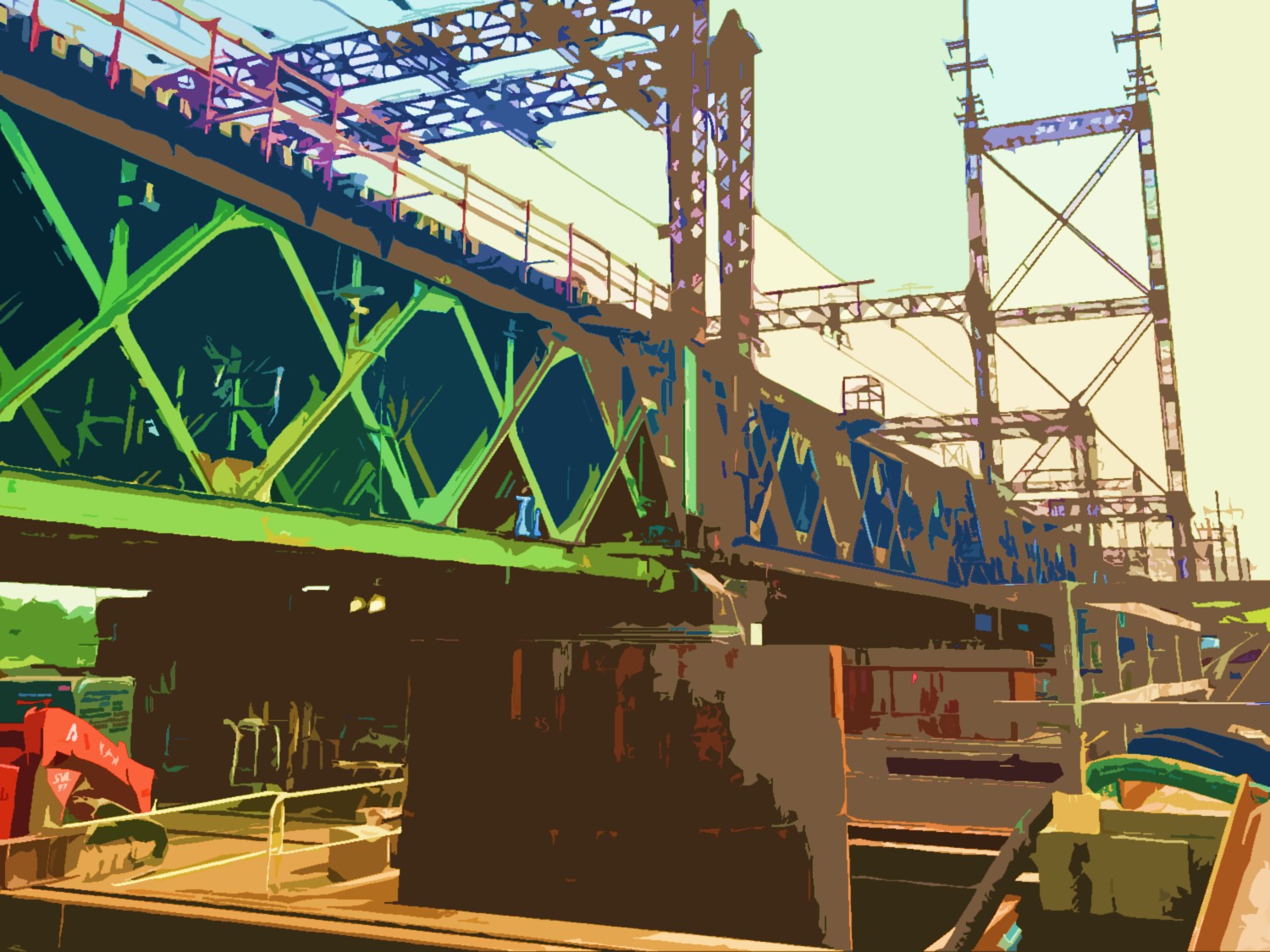

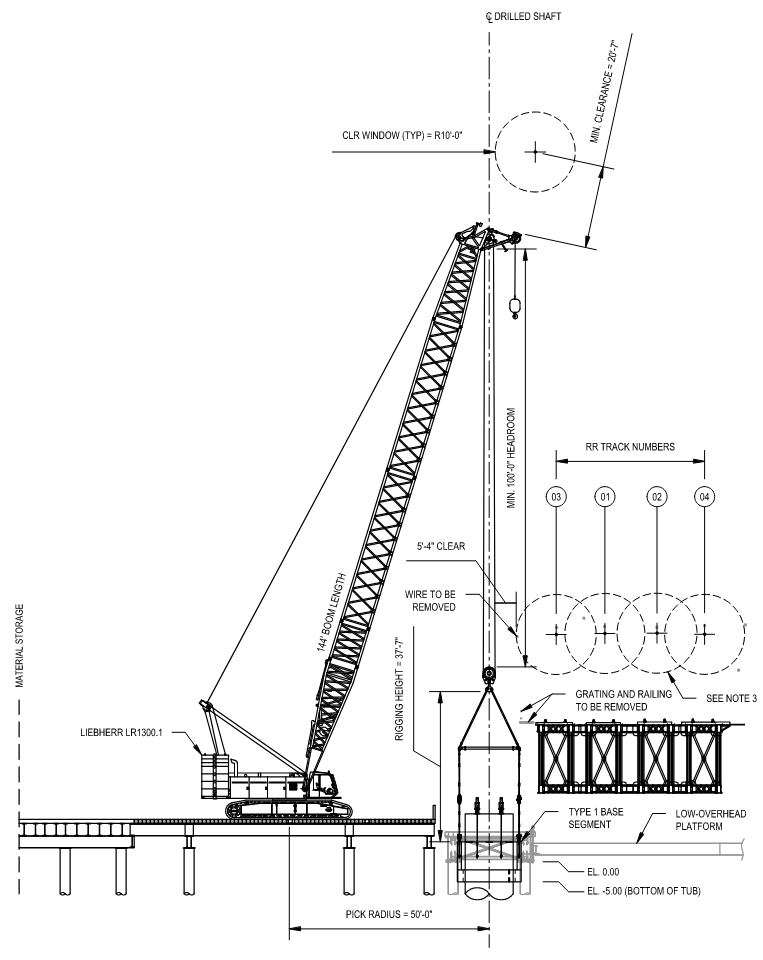

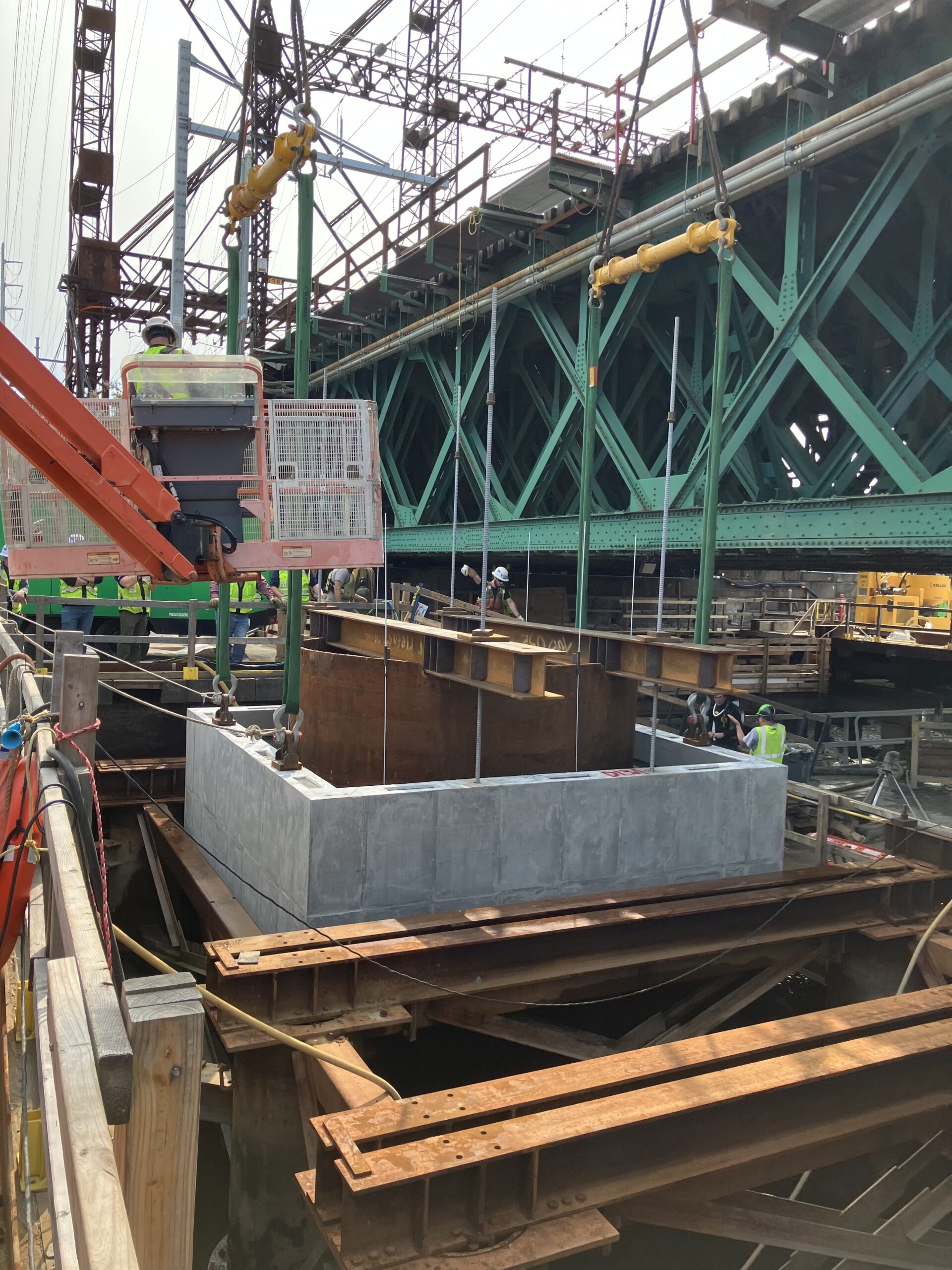

Constructing vertical lift bridge tower foundations at the WALK Bridge Replacement project involved lifting large-diameter drilled shaft and micropile casings (7–12 feet in diameter), reinforcing cages, and precast tubs weighing between 22 and 73 tons. Each lift’s proximity to an active railroad and energized overhead powerlines posed significant logistical challenges. Additionally, the crane needed to work from a trestle with minimal real estate for staging material.

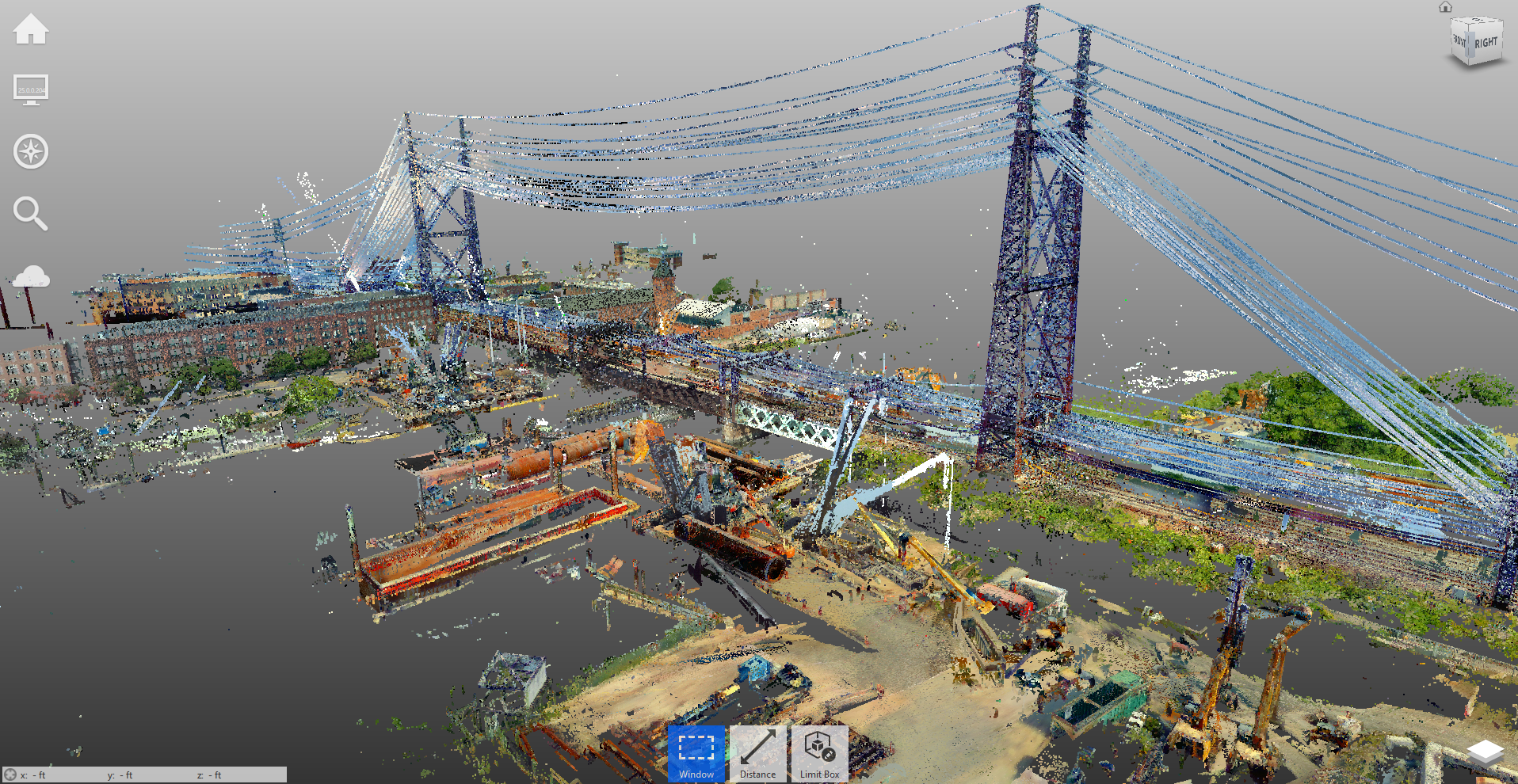

3D scanning provides accurate data

The CMJV scanned the entire project to identify and locate site features that could impact work, including overhead utilities, railroad bridge, and railroad approaches. JARC provided 3D scanning post-processing services to convert point cloud data into accurate, usable CAD elements. 3D scanning enabled highly accurate identification of clearances to energized lines and rail operations, helping the joint-venture determine whether operations could proceed as planned, required temporary outages, or necessitated line removal.

With critical features from the 3D scanning analysis located in CAD, JARC produced Field Shop Drawings that indicated all details and maneuvers of the crane lift. The drawings were specific to the crane make, model, and serial number used in the operation.

While scanning, CMJV recorded the ambient temperature and wind speed. The sag in each wire varies with temperature and since 3D scanning took place during the hottest months of the year, wire elevations were at their lowest. The Field Shop Drawings reflected the wire elevations from point cloud data and indicated the date that 3D scanning was performed.

Plans were executed successfully

Field Shop Drawings were submitted to the railroad for review and approval prior to executing the field work. The 3D scanning analysis and subsequent detail provided within the drawings facilitated shorter review durations. Rigorous planning and engineering support helped successfully execute the work with minimal disruption to rail operations and without compromising safety. As a result, the team installed critical foundation components with tolerances as tight as two inches.

“The operation went really well. Field layout and geometry looked just as it was depicted in the drawings from JARC,” said Taylor Moon, a Senior Project Engineer at CMJV who worked closely with JARC in planning the lift.

Learn more about the project at https://www.walkbridgect.com/